Photoelectric display

Mar 14,2025

1、Properties and Functions of Core Materials

● Transparent conductive characteristics

ITO material consists of 90% indium oxide (In₂O₃) and 10% tin oxide (SnO₂). Free electrons are generated through Sn⁴⁵ doping within the In³⁺ lattice, enabling a balance between excellent conductivity (resistivity <1×10⁻⁴ Ω·cm) and high transmittance (over 80% in the visible light range).

Its wide band gap of 3.7 eV allows strong ultraviolet absorption while maintaining transparency in the visible spectrum, making it ideal for use as transparent electrodes in display devices.

● Film preparation process

The ITO target creates a nanoscale film, approximately 100–300 nm thick, through magnetron sputtering or evaporation. The film's uniformity and density play a critical role in determining the display device's response speed and color accuracy.

2、Main application areas

● Flat panel display

LCD/OLED transparent electrode: ITO film serves as the transparent electrode in liquid crystal displays (LCDs) and organic light-emitting diodes (OLEDs). It enables precise pixel control through its excellent conductivity while maintaining over 90% light transmittance, ensuring high display brightness and vivid color saturation

Touch screen conductive layer: ITO film functions as the conductive layer for the sensing component of capacitive touch screens. Its low resistivity enables rapid processing and response to multi-touch signals

● Flexible display technology

ITO film enables the transparent electrode for foldable screens by utilizing flexible substrates, such as PET. It ensures both flexibility and conductive stability, making it ideal for advanced technologies like foldable smartphones and flexible OLED displays

● Optoelectronic device integration

Solar cell transparent electrode: As a transparent conductive layer in thin-film solar cells, ITO film effectively balances light absorption with current collection efficiency, enhancing overall solar cell performance

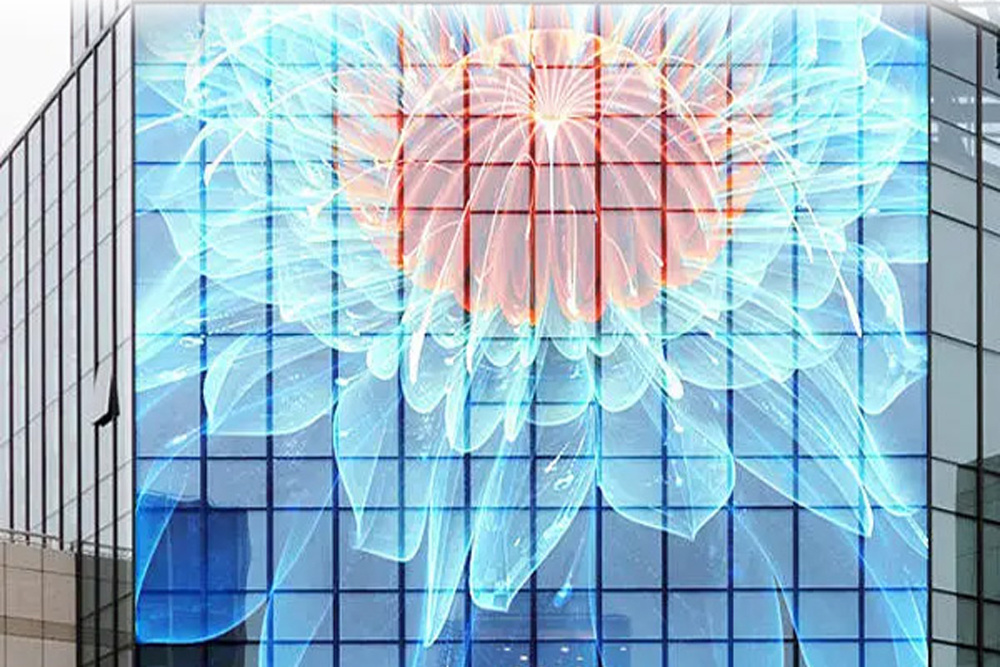

Electronic paper and transparent display: Leverages the high light transmittance and low haze properties of ITO film to meet transparent conduction needs in non-backlight display environments

3、Technical advantages and industry position

● Performance advantages

High stability: ITO film retains its conductivity and transmittance even under high temperatures (below 300℃) and high humidity, making it suitable for the demanding processes involved in display panel manufacturing.

Process compatibility: It exhibits excellent bonding with various substrates such as glass and plastic, supporting efficient, large-scale roll-to-roll production24

● Market dominance

The global ITO target market continues to grow, and China's demand accounts for more than 40%, mainly driven by the popularity of smart phones, in-vehicle displays and smart wearable devices.

Previous:

Next:

豫公网安备41032602000214号

豫公网安备41032602000214号